Follow along to make a simple dining table that can be customized to fit your own space and decor.

This project was originally posted on Instructables

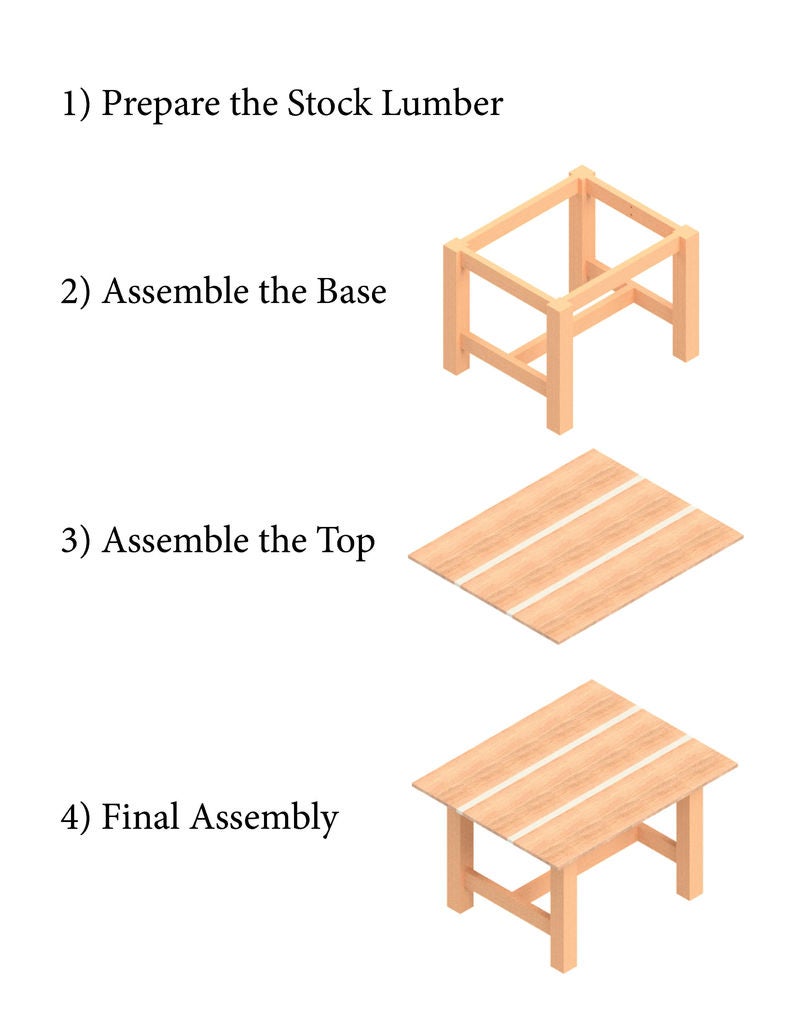

Overview

This past August we moved into a new apartment so we could decrease the total number of people we lived with and transition into a home that was “more adult-like” and less “fresh out of college-like”. In doing so, we were losing a roommate who had supplied our dining table for the past two years, and were looking for something that would better fit our style. Being an engineer (and due to my personality in general), I decided it would be worthwhile to build our own dining table. The overall process is fairly straightforward, and I think anyone can follow along and adapt the design to fit their own space and style. It’s definitely a good feeling sitting down for dinners knowing you’re using something you first designed and then brought to fruition yourself. In the end, I believe the table materials (lumber + hardware + stains and polycrylic) only cost me around $125 which is extremely low considering the next closest option (of the Swedish variety) would have been around $200 minimum.

Side note: If you enjoy this Instructable then feel free to vote for me in the Furniture contest!

Step 1: The Design

Keep in mind that we in the Bay Area, CA, so for that reason I wanted something that could be built within a limited space (namely on our ~5′ x 17′ balcony) and was feasible with my limited tools. For this reason, the design is fairly simple and doesn’t feature complex joinery or woodworking methods. Ideally this makes it pretty easy for anyone to create while still making a finished product that impresses all house guests and should stand up to the tests of time.

The design itself borrows elements from a farmhouse style table. I spent many hours looking over images of tables on the internet, along with what was available in stores for inspiration. Naturally I wasn’t the first one to have the idea to make my own table, and many other creators have posted their process to YouTube which I also found to be a great resource for the overall design and techniques used (see links below).

The main things to consider are the height of the table and how many people you want it to fit. There were only going to be three of us using it regularly, but we like to have the occasional game night so wanted the potential for more than that to sit comfortably. In our case, we already had three chairs so I looked to see what the optimum table height would be and how many chairs we could put between the legs. In the end, the table is 28.5″ tall with a 38.5″ x 47.75″ surface. In its normal configuration, we have a chair on three of the four sides with a small bench on the final side. For some occasions, we’re actually able to move the chairs to straddle the legs and can squeeze in four extra people fairly comfortably (compared to the normal four it sits). All in all it’s a good size for everyday use and versatile for special occasions.

References:

Modern Split-Top Dining Table by Modern Builds

How to build a Farmhouse Table Complete Start to Finish by Wood & Screw

Step 2: Materials and Tools

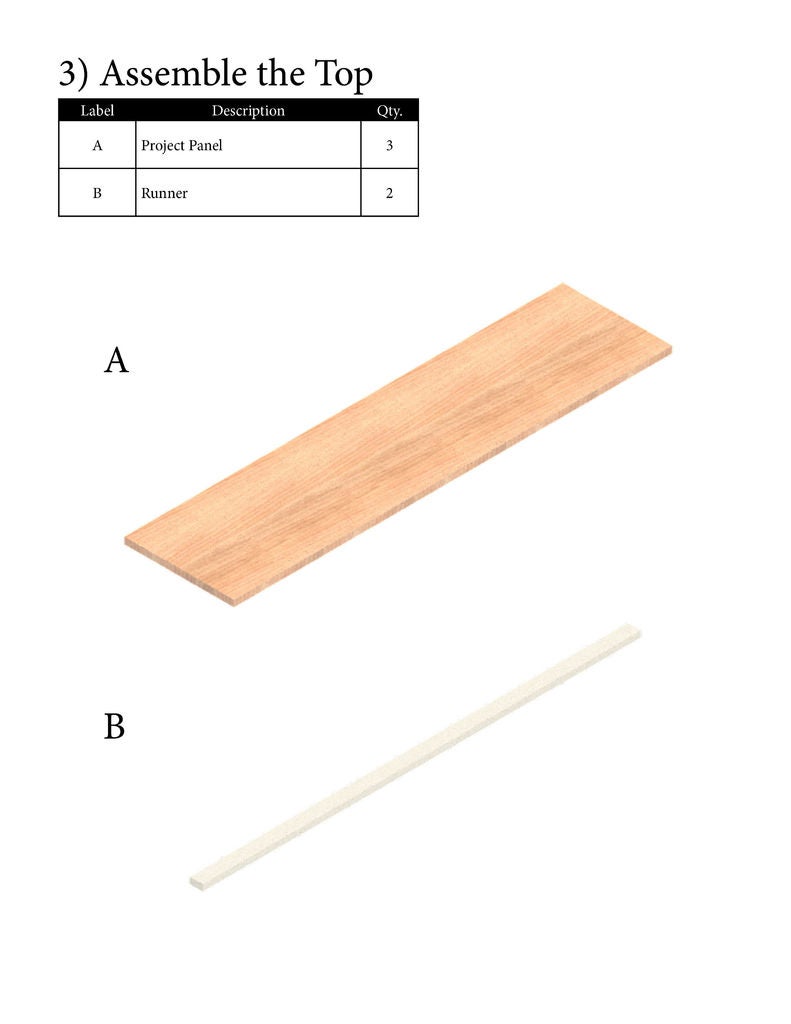

I wanted to keep the overall cost of the table down so I chose to use dimensional construction lumber from my local big box hardware store. The legs are made of 4×4’s and the rest of the base is made from 2×4’s. As expected, my initial design didn’t transfer too smoothly from computer to actual practice. I initially wanted to use 2×10’s glued together to form the top, however, the wood I picked out ended up being too bowed / curved / a number of other problems, so I had to scrap these and use pre-glued project panels. In order to make the 2×10’s work, I suggest using a planar / jointer / table saw to make the boards flat and edges as straight as possible to ensure a successful glue up (see link below for some good videos on how to do this correctly). The project panels already have this done to them, so it eliminated all the gaps and imperfections I was seeing in my initial attempt. This brought the material cost up and made for a thinner tabletop, but in the end it works well with the rest of the design and gives a refined final product.

Materials Used:

– (2) 2″ x 4″ x 8′ (used for apron and leg supports)

– (2) 4″ x 4″ x 8′ (used for legs)

– (3) 12″ x 4′ x 0.75″ Project Panel (used for the top)

– (2) 1.5″ x 4′ x 0.75″ Runner (found near the project panel at Lowe’s)

– (2) 1/2″ x 4′ Dowel (used for structural joints)

– (1) 3/8″ x 4′ Dowel (used to plug pocket holes, optional)

– (14) 2.5″ #8 Pocket Hole Screws

– (8) Table Top Fasteners & Screws

– Stain (I used Ebony and Fruitwood)

Tools Used:

– Measuring Tape

– Circular saw

– Drill

– Random Orbital Sander

– Trim Router

– Pocket Hole Jig

– Flush Cut Saw (or any hand saw)

– Right Angle or Square

– Toggle Clamps

– Truck Tie Downs (they’re cheaper than large clamps and work just as well)

– Paint Brush

– 3D Printer (optional)

– 3D Printer Dowel Jig – 2 x 4 and 4 x 4 (optional, both attached)

References:

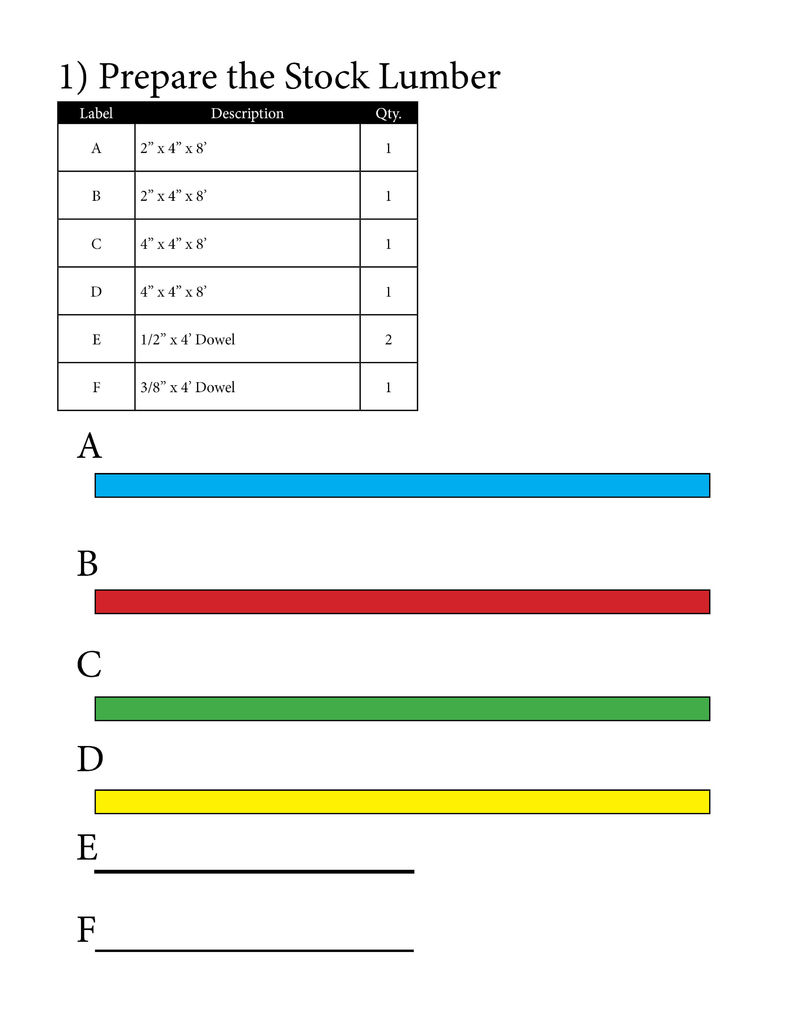

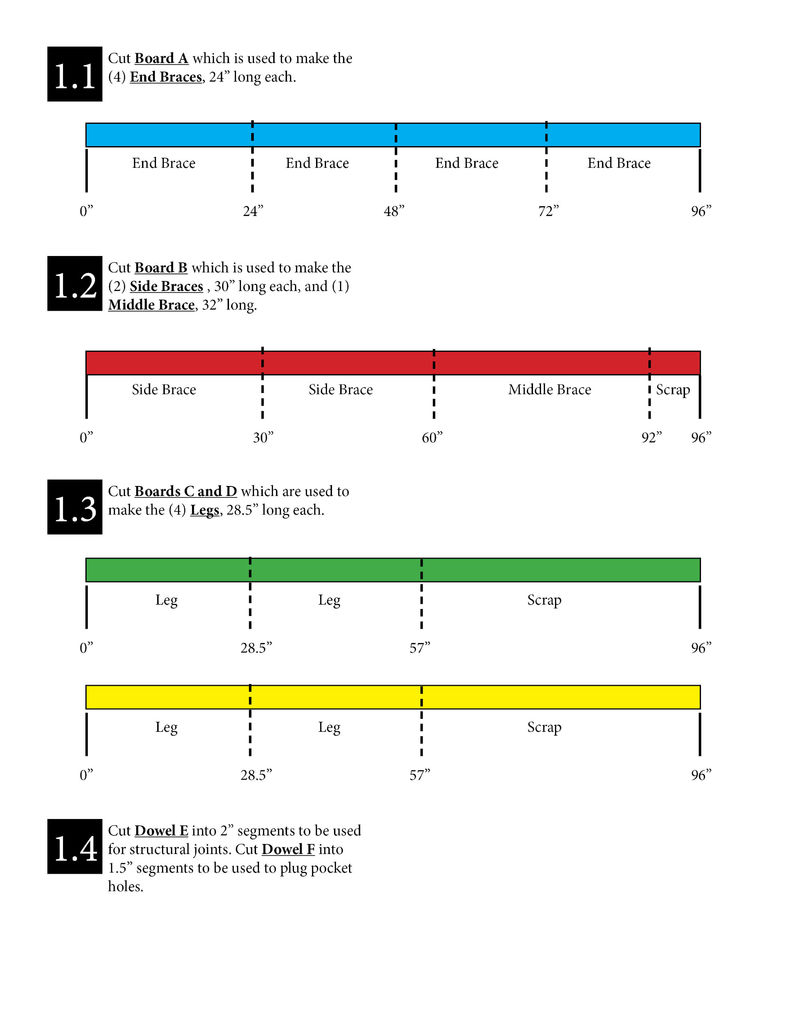

Step 3: Prepare the Stock Lumber

Once you have your lumber, the next step is to cut everything down to size. As with any other woodworking project, make sure to always measure twice and cut once so you don’t waste any materials. Since my car couldn’t actually fit the lumber, I ended up going home for a weekend and enlisted my parents help to gather materials. As a result, I made most of the cuts using my dad’s large radial arm saw, however the same cuts can be made easily with a circular saw.

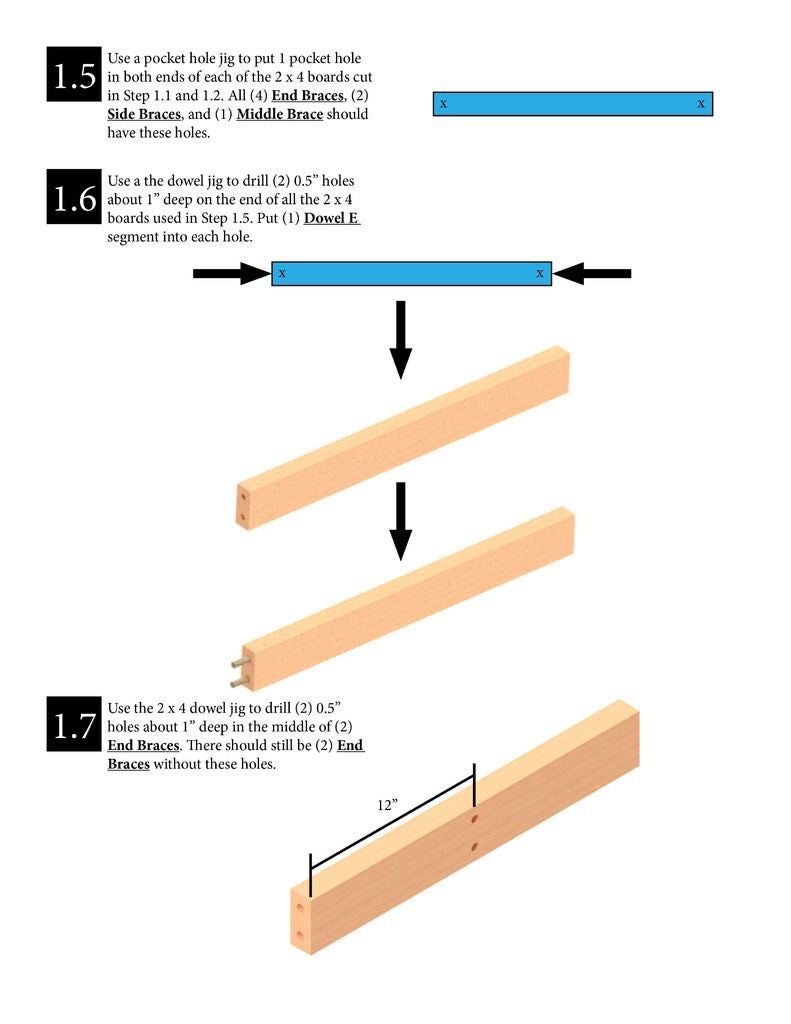

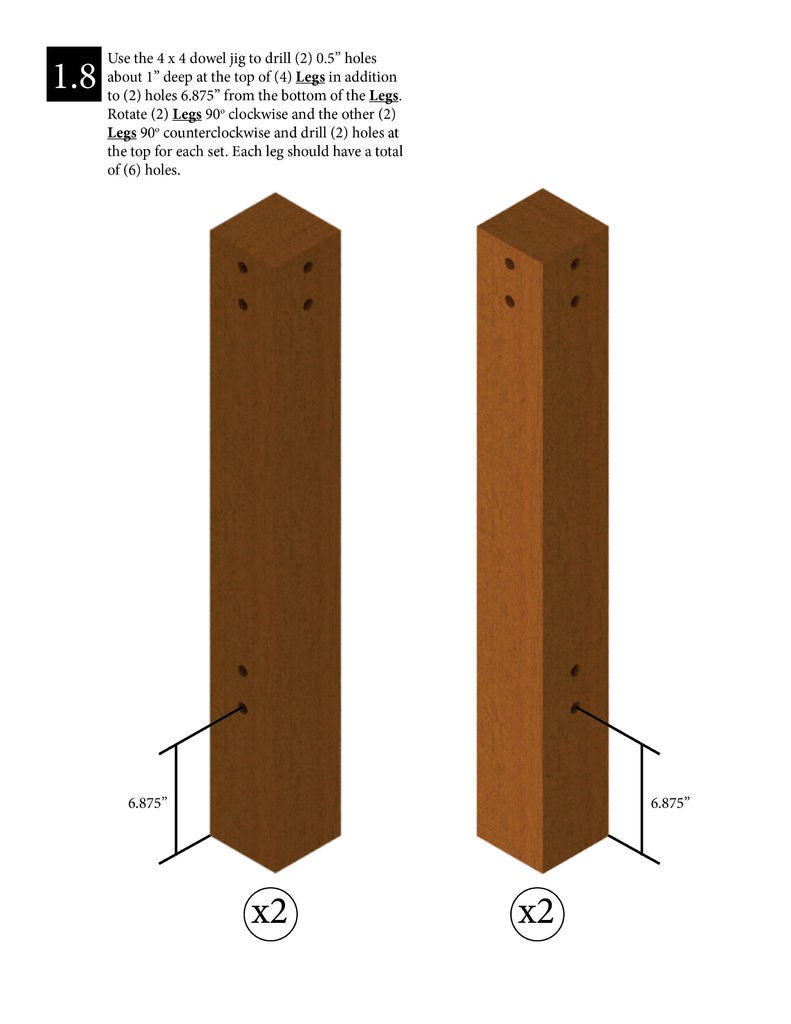

The cuts to be made are attached. Some of the pieces are close in length, so it’s helpful to label them to make it easier later on. In addition to the cuts, you’ll need to drill holes in some of the pieces for the dowels. I like to use my 3D printer to make jigs to help with consistency, however the same holes can be made using a cardboard template or just measuring the locations. In this case, the jigs helped to make sure the holes were always centered in the posts and in the correct spots at the end of the different 2×4’s.

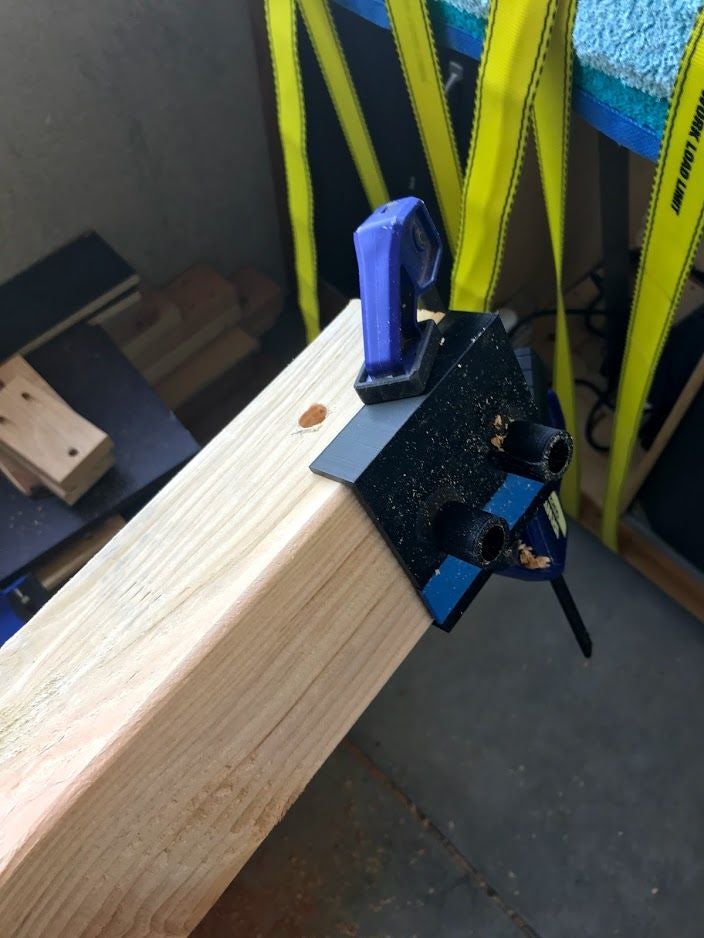

It’s easiest to drill all the pocket holes before you put anything together. I initially planned on using another 3D printed jig for these pocket holes, but ended up just buying a Kreg jig (I definitely recommend this and think it’s worth the money). It’s also helpful to load in the pocket hole screws ahead of time to avoid trying to fit the drill in tight spaces during assembly.

Once all the pocket holes are drilled, glue in dowels to the holes holes mentioned above. Only glue in one side of the dowel since a dry fit will be performed (the other side of the dowel can be glued at final assembly but isn’t necessary).

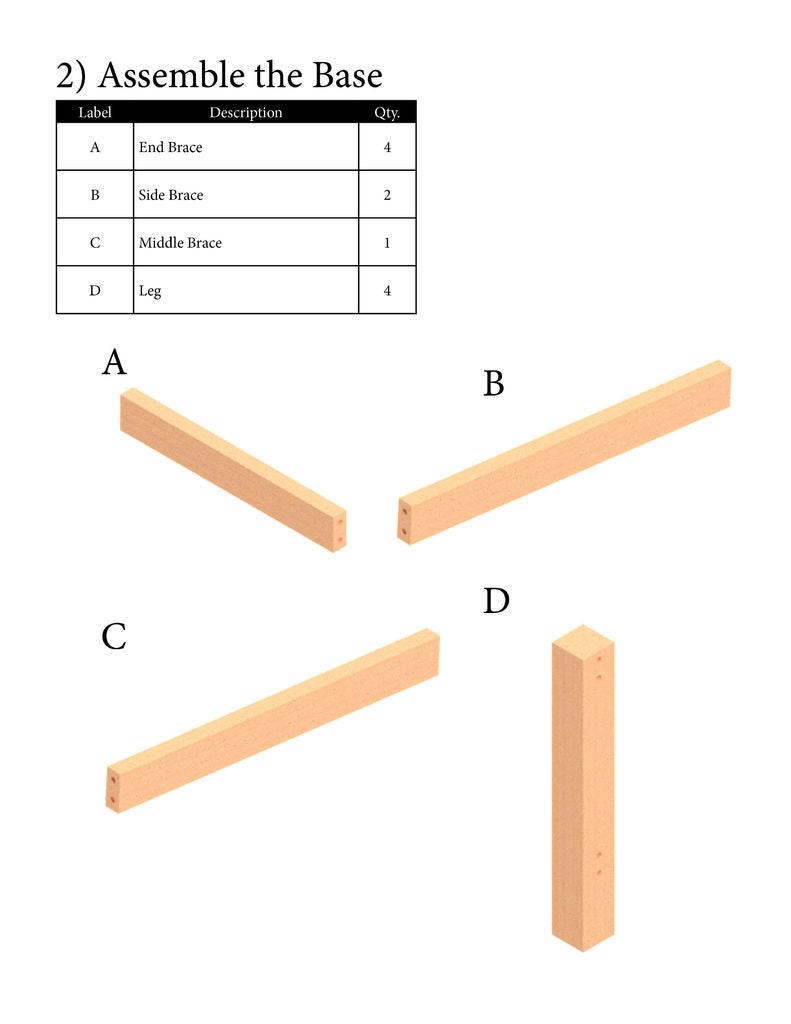

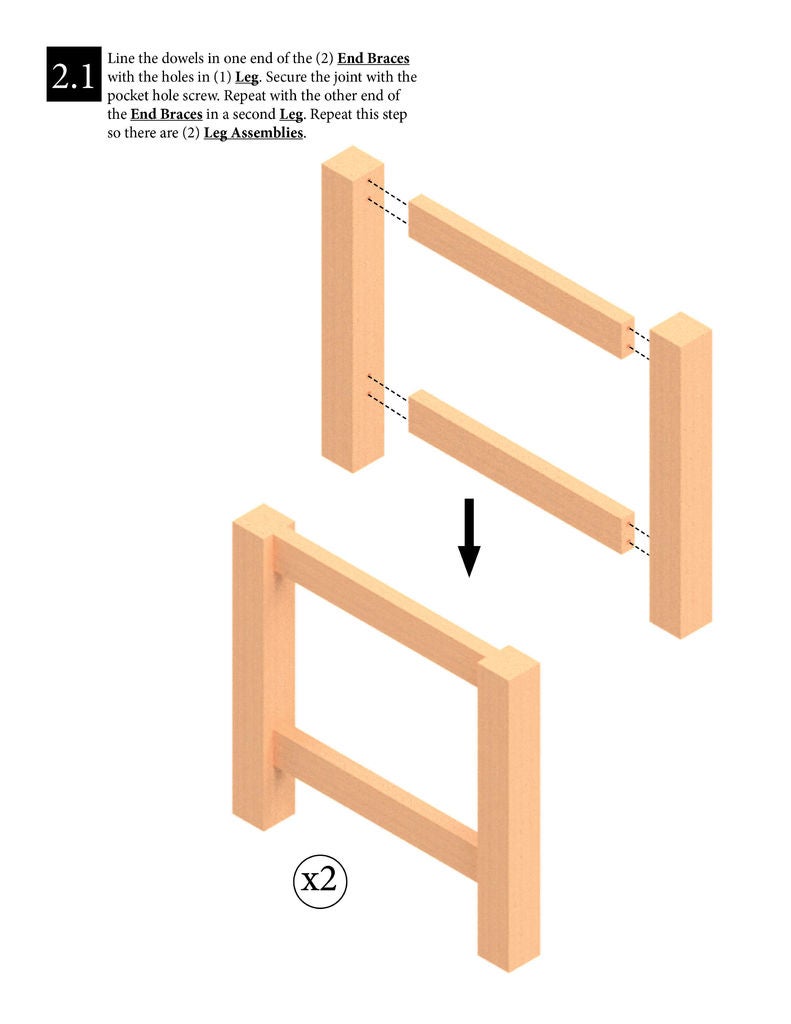

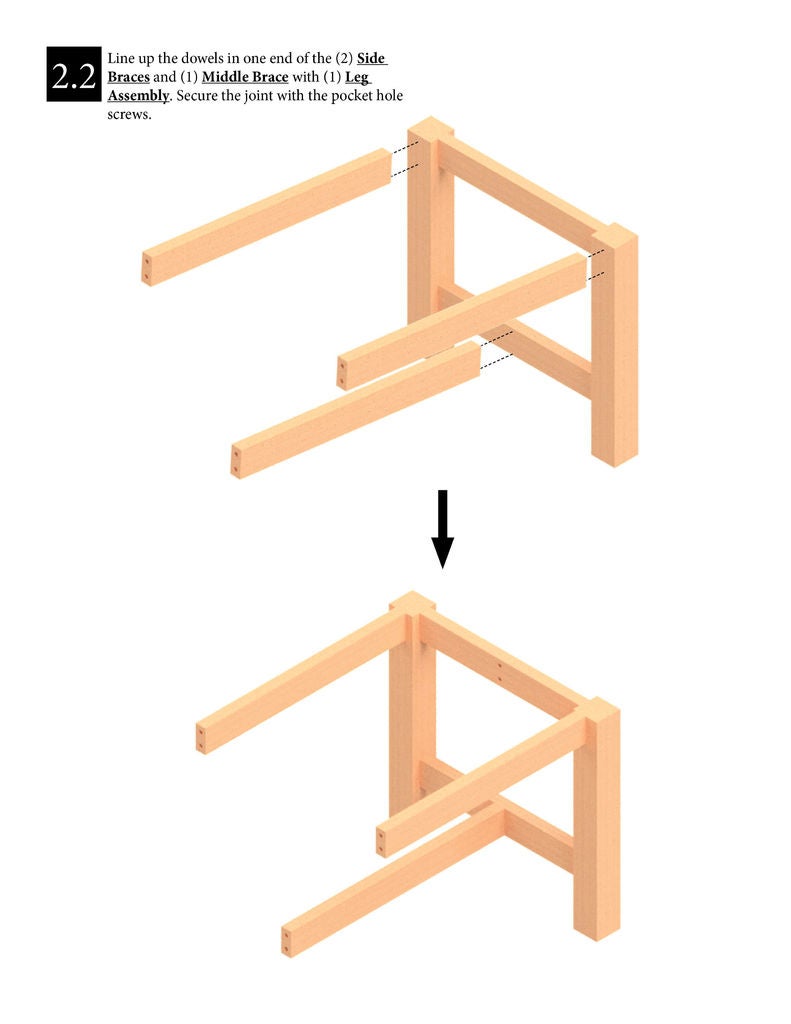

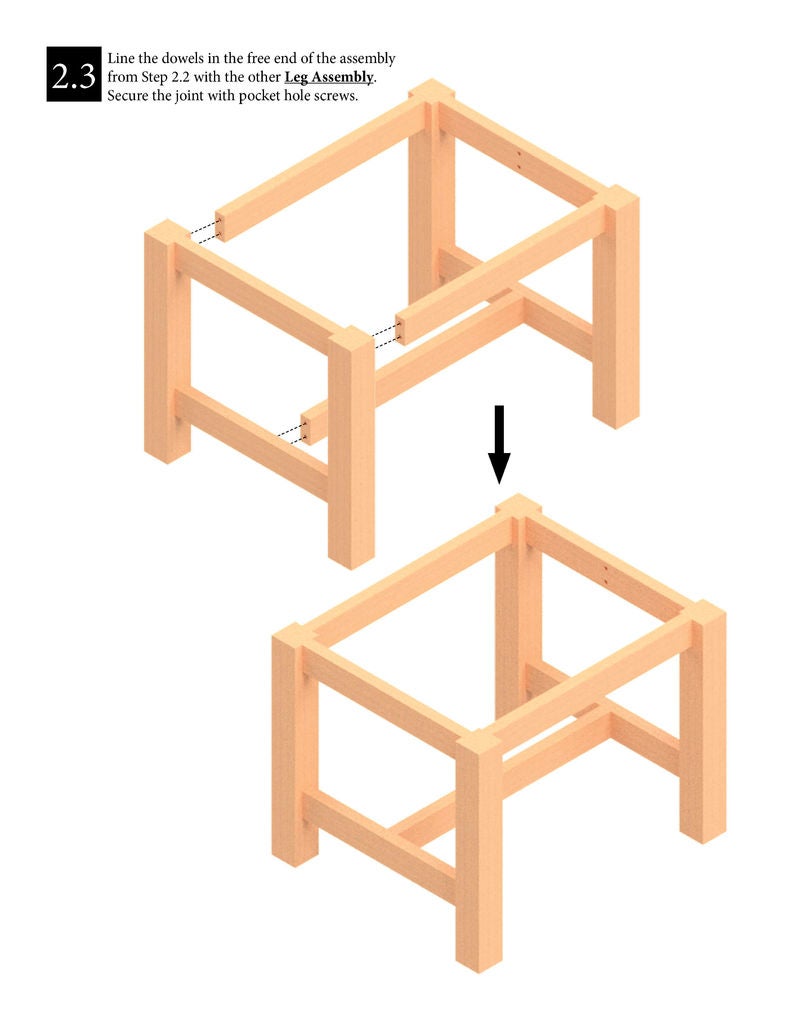

Step 4: Assemble the Base

The legs should be assembled using the dowels to guide them into place. Racheting straps can be helpful to pull the members tight together and eliminate any gaps. Once this is done drive in the pocket hole screws to fully bring everything together.

To make everything a little cleaner, I plugged the pocket holes with a dowel and cut it flush to make hide the hole a little better. In my case, I wanted the ability to take the legs apart from each other so I chose to leave the pocket holes attaching the Side Braces and Middle Brace unplugged which still gives me access to the pocket holes themselves. The pocket holes are fairly hidden anyways, so this isn’t entirely necessary.

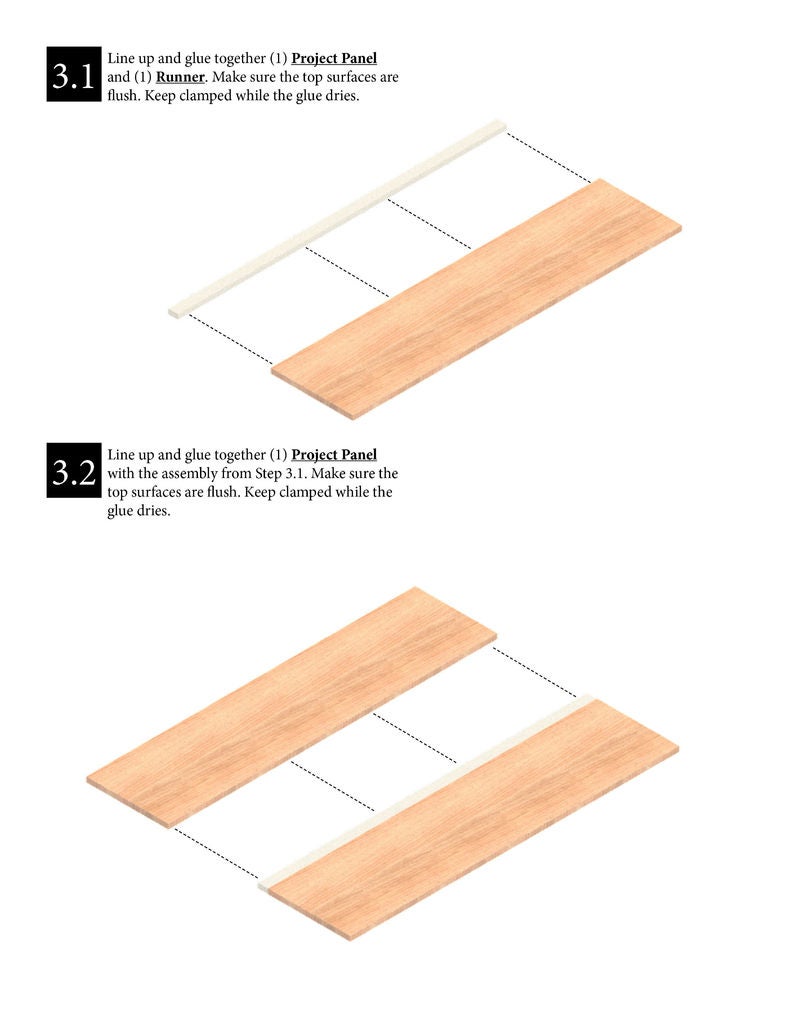

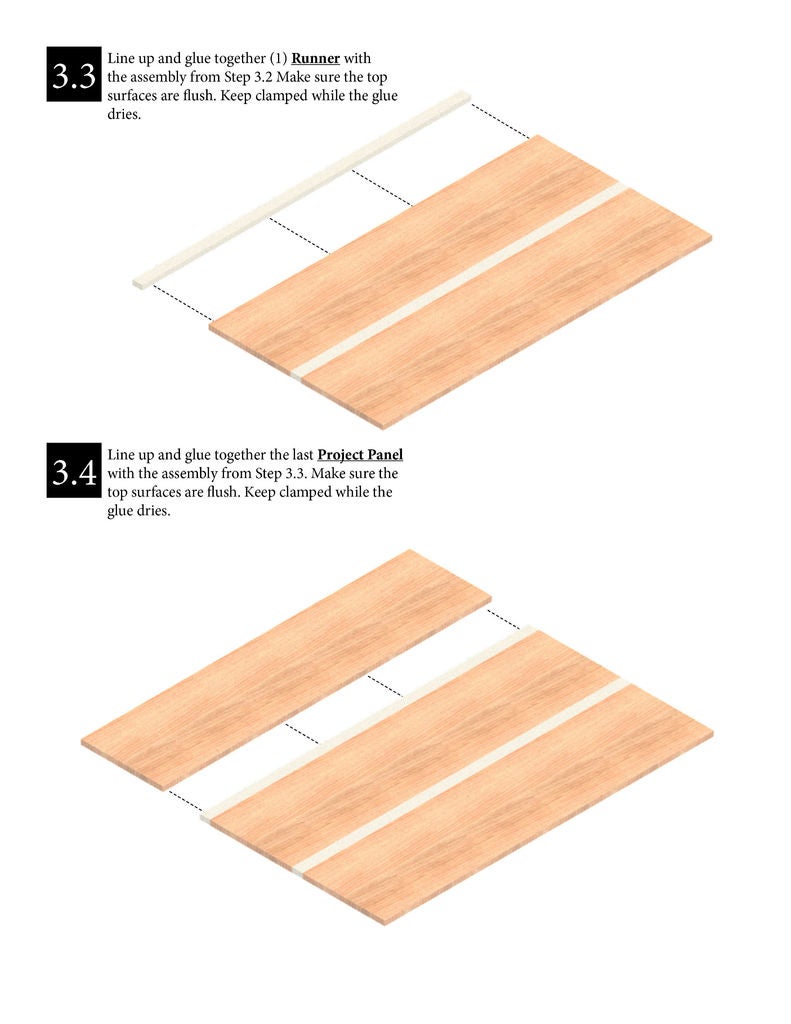

Step 5: Assemble the Top

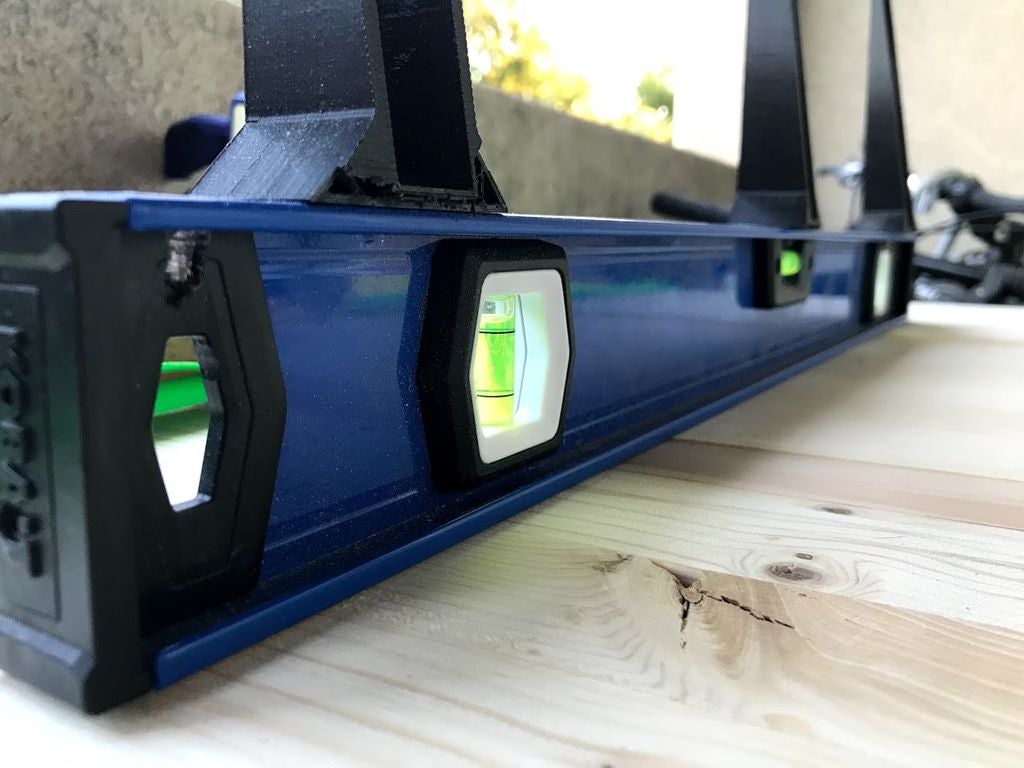

The project panels need to be glue to each other to make the table top. In my case, the three project panels by themselves didn’t give a wide enough table, so I chose to add a runner between each set of panels. This added a little bit of width in addition to giving a unique break so the table top has a slight color change in these locations. Spread some glue along the edge of a panel and line it up with the next panel. Next use the racheting straps to pull the boards tight together. Careful to not tension the straps too much otherwise the boards may start to bow or cup. Also make sure to line one end of the boards up to avoid extra cleanup later on. It’s best to do two boards at a time and then add one on after the first set is dried.

Once everything’s assembled and glued up, use a circular saw on either end to create a straight edge if necessary. Also go back and sand the surface with increasing grit (I used 80 up to 220) to clean up the glue seams and level out the surface where necessary. In some places I used some wood filler to hide small gaps.

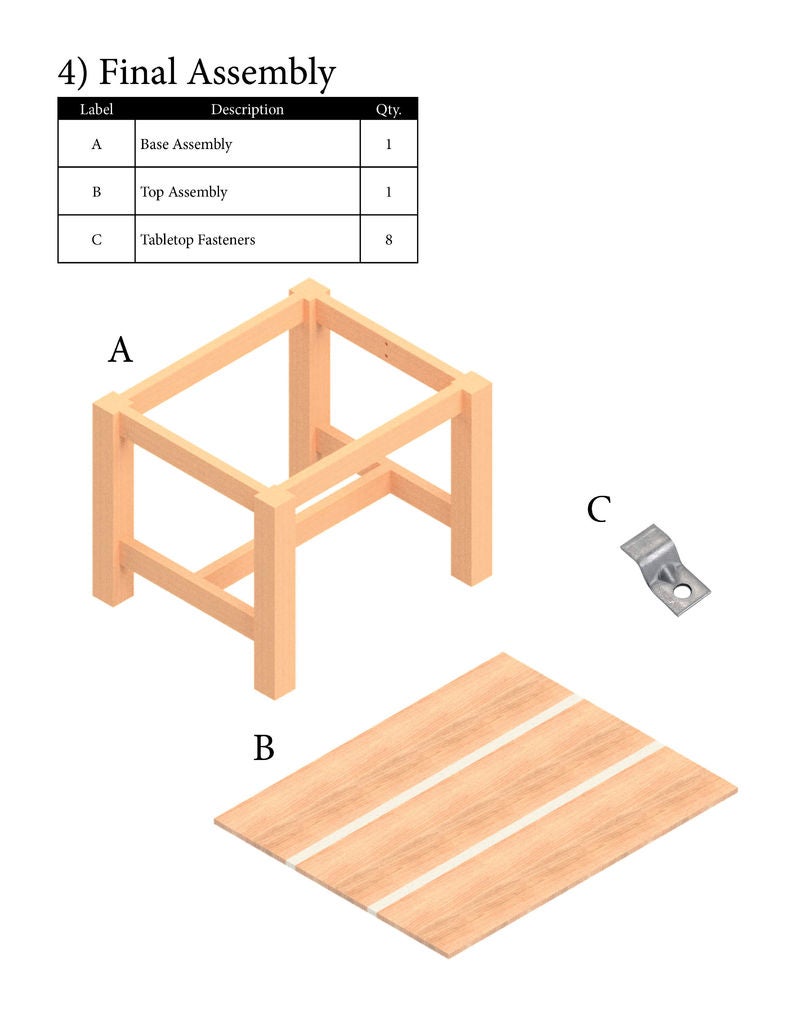

Step 6: Put It Together

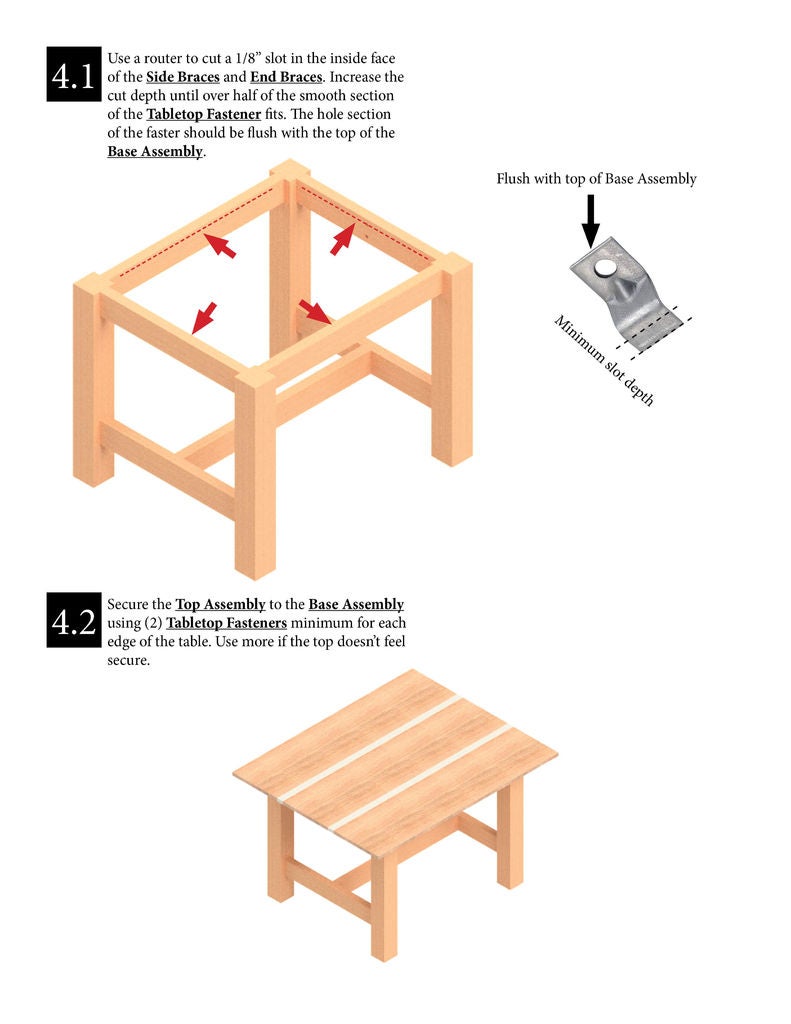

Something important I learned by doing this project is the fact that wood can expand or contract depending on the humidity of the room. This is very important, especially for attaching the top of the table to the legs. If just screws are used, the top surface is at risk of adjusting over time and will split with the wood movement. To avoid this, special table top fasteners are used with slots that will allow the fasteners to slide with the wood over time (see links below for some further information on this).

A trim router can be used with a 1/8″ bit to put a slot around the inside edge of the apron. Then use the fastener to make sure the depth is correct (the fastener should fit about halfway into the slot). Next center the top on the leg assembly and clamp it down to avoid any movement. Then screw several fasteners into place to secure the top (I used two to three per edge). Double check the top is secure and add more fasteners as necessary.

I also had some leftover 2 x 4’s, so I chose to put some angle braces in each corner to help keep the table base square. This step is also not completely necessary, but helps add to the durability of the table.

References:

Allowing For Wood Expansion on Solid Wood Tops by WoodWorkers Guild of America

How to Attach a Table Top by The Homestead Craftsman

Quick Tip: Assembling your Table Top to the base and Aligning by Peter Dettorre

Step 7: Add a Finish

Once everything fits together smoothly the next step is to prepare it to be finished. First sand everything down with increasing grits (I started at 80 and went to about 220). Not all surfaces need such a high grit so use your best judgement to determine when sanding is complete. I spent awhile on the top to make sure it was nice and smooth to make sure it was flat and smooth. I also added a small round over using my router along the edge of the top to break the hard corner and make it more comfortable to lean on.

Once sanding is done, wipe everything down to make sure all excess dust is gone before staining everything. This is one of my favorite steps since we get to customize the piece and make it something that’ll fit in it’s final place. Since we already had some Ebony chairs, we chose to stain the legs of the table to match. The top was then stained Fruitwood since we thought it would lighten up the piece and contrast the dark legs. One thing to note (probably obvious to most people) is to make sure you shake the can of stain well to get the pigment all mixed in. The first few coats we did were fairly watery since we forgot to do this so we initially didn’t get the results we expected. We then applied a second coat or two until we had a color we liked and everything was well covered.

After finishing staining you’ll want to protect everything with a coat or two of polycrylic. We chose a water based product as the oil based ones are reported to add a slight yellow tint to the wood. In the end, this coating should seal the wood to help it last in addition to protect it from any water or heat damage it might see when being used on a daily basis. So far it’s held up fairly well, but if the coating starts to degrade then we can just add another coat on.

Step 8: Use It!

If you made it this far then you’re done! Hopefully you’ve found this Instructable helpful and it’s led you to create a piece of furniture that should last for awhile. All in all I think this was an enjoyable project that didn’t require much expertise or special tools, and I hope you too will find joy in making something you can use on a regular basis. Let me know if you have any questions in the comments or any tips for anyone else planning to try to make their own furniture!